Cuplock Scaffolding System

Cuplock Scaffolding System Specification

- Color

- Blue, Silver, Red, Custom on request

- Constitute

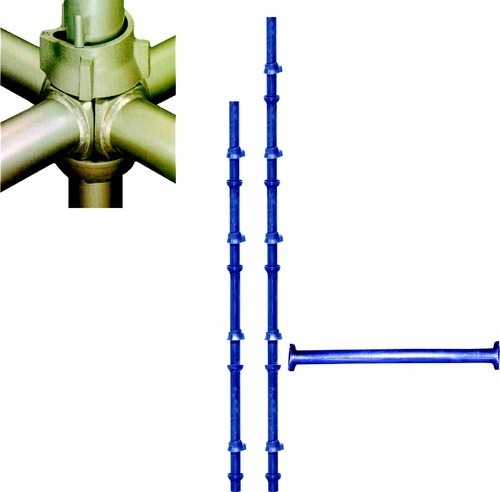

- Steel Tubes, Forged Cups, Bottom Cups, Top Cups, Blades

- Weight

- Standard Ledger: 5.8 11.2 kg, Standard: 7.5 16.5 kg

- Pin

- Forged Blade/Pin, Welded on Standards

- Prop Head

- Universal Jack Head, Adjustable U-Head

- Sleeve size

- 200 mm - 250 mm (Standard joint sleeve length)

- Features

- High load capacity, Rigid Connections, Easy to Assemble/Disassemble, Corrosion Resistant, Versatile for Multiple Configurations

- Technique

- Welded, Hot Rolled

- Product Type

- Scaffolding System

- Material

- Mild Steel (IS 1161/IS 1239 Grade)

- Components

- Verticals (Standards), Horizontals (Ledgers), Diagonal Braces, Base Jacks, Cantilever Frames, Intermediate Transoms, Hop-up Brackets, Cuplock Scaffolding Boards, Toe Boards

- Diameter

- 48.3 mm

- Width

- 1.2 m, 1.25 m, Custom sizes available

- Length

- 0.6 m to 3.0 m (Ledgers), 0.5 m to 3.0 m (Standards)

- Height

- Up to 24 m (Standard design), custom heights available

- Thickness

- 3.2 mm - 4 mm (Standard tube thickness)

- Platform Loading Capacity

- 1.5 2.0 kN/m

- Surface Treatment

- Hot Dip Galvanized/Painted/Powder Coated

- Application

- Building Construction, Bridge Construction, Refineries, Shipyards, Maintenance & Repairs, Access Structures

- Size

- 48.3 mm OD x 3.2/3.6/4 mm Thickness

- Ledger Blade Type

- Forged Ledger Blade

- Standard/Tube Surface Finish

- Smooth/Shot Blasted

- Temperature Resistance

- -20°C to 55°C

- Top Cup Material

- Malleable Cast Iron or Forged Steel

- Standard Lengths Available

- 0.5 m, 1.0 m, 1.5 m, 2.0 m, 2.5 m, 3.0 m

- Standard Cup Spacing

- 500 mm or 1000 mm

- Compatibility

- Compatible with steel or timber boards

- Connection Method

- Cup-lock (No bolt fittings required)

- Vertical Tube Standard Marking

- At every 500 mm for quick placement

- Manufacturing Standard

- IS 1161, BS 1139, EN 12810/EN 12811

- Design Safety Factor

- 2.0 - 2.5

Cuplock Scaffolding System Trade Information

- Minimum Order Quantity

- 50000 Kilograms

- Payment Terms

- Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 1-2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

About Cuplock Scaffolding System

With the support of our adept team of professionals, we bring forth a broad assortment of Vertical Cup Lock System, that is quite versatile in its use and can be seen in construction. This is self supporting and the fourth vertical can now be connected by a further ledger and the bay leveled. Our offered cup lock system is offered in different specifications as per the requirements of the customers at pocket friendly rates. Vertical Cup Lock System is demanded in constructing huge complexes, building extensions, roofing and building renovation.

Technical Specifications

| Thickness | 1-2 Inch |

| Material | Mild Steel |

| Surface | Galvanized |

| Size | 1-6 Feet |

Innovative Cup-Lock Connection System

Designed to facilitate rapid assembly without bolts, the Cuplock Scaffolding System employs a unique cup-lock mechanism. Forged steel and malleable cast iron ensure secure and rigid connections between verticals and ledgers. This system enhances site efficiency, minimizes manual handling, and allows tool-free erection, making it a preferred choice for various construction applications.

Versatile and Customizable Configurations

The system can be easily configured to suit diverse site requirements. With standard lengths from 0.5 m up to 3.0 m and vertical tube markings every 500 mm, precise and flexible layouts are achievable. Its compatibility with both steel and timber boards, multiple surface treatments, and custom size options make it ideal for unique project needs.

Safety, Durability, and Compliance

Manufactured under strict standards (IS 1161, BS 1139, EN 12810/12811), the cuplock scaffolding ensures high loading capacities and safety. With a design safety factor of 2.02.5 and operating temperatures from -20C to 55C, it is well-suited for demanding conditions. Shot-blasted or smooth tube finishes enhance durability and corrosion resistance.

FAQs of Cuplock Scaffolding System:

Q: How does the cup-lock connection method improve assembly efficiency?

A: The cup-lock system eliminates the need for bolts or loose fittings by using quickly positioned top and bottom cups. This simplifies assembly and disassembly, significantly reducing labor time and allowing for faster project turnaround.Q: What are the main benefits of using cuplock scaffolding for construction projects?

A: Cuplock scaffolding is valued for its high load capacity, rigid connections, corrosion-resistant finishes, and versatility in creating various configurations. This makes it suitable for building, bridge, refinery, and shipyard projects requiring reliable and safe access structures.Q: When should I consider using cuplock scaffolding over traditional scaffolding systems?

A: Opt for cuplock scaffolding when projects demand rapid installation, modular layouts, and a strong, stable platform. Its design is ideal for projects with changing requirements or tight construction timelines.Q: Where can the cuplock scaffolding system be deployed?

A: This system is commonly used in building and bridge construction, industrial maintenance, shipyards, and repair works. Its adaptability also suits temporary access solutions and structures up to 24 meters high, with custom heights available.Q: What process is followed to ensure the scaffoldings safety and quality?

A: Each component is manufactured to comply with IS 1161, BS 1139, and EN 12810/EN 12811 standards. Quality includes precise tube marking, forged ledger blades, and hot-dip galvanizing or powder coating for corrosion protection. Regular inspections and adherence to recommended load capacities further assure safety.Q: How is the cuplock system adapted for different platform widths and lengths?

A: Standard widths are 1.2 m and 1.25 m, with custom sizes available. Ledgers and standards are available in lengths from 0.5 m to 3.0 m, supporting a range of site requirements. This flexible sizing enables tailored scaffolding layouts for almost any application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cup Lock System Category

Scaffolding Fittings

Price Range 70.00 - 130.00 INR

Minimum Order Quantity : 100 Pieces

Technique : Other, Forging/Welding

Thickness : 3.2 mm

Length : Varies based on type

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese