Scaffolding H Frame

Scaffolding H Frame Specification

- Technique

- Welded

- Color

- Blue/Red/Custom

- Features

- High Durability, Corrosion Resistant, Reusable, Easy to Assemble/Disassemble

- Pin

- Cup Lock / Pin Lock

- Constitute

- Steel Tubular Structure

- Sleeve size

- 60 mm

- Prop Head

- Standard U Head/Flat Head (optional)

- Weight

- 18-22 kg per frame

- Product Type

- Scaffolding H Frame

- Material

- Mild Steel (MS)

- Components

- Main Frame, Cross Braces, Joint Pins

- Diameter

- 48.3 mm

- Width

- 1250 mm

- Length

- 2000 mm

- Height

- 2000 mm

- Thickness

- 2.6 mm

- Platform Loading Capacity

- Up to 250 kg per frame

- Surface Treatment

- Painted / Powder Coated / Hot Dip Galvanized

- Application

- Construction, Maintenance, High Rise Building Works

- Size

- 2000x1250 mm

- Customization

- Dimensions and Color Available as per Request

- Horizontal Pipe Thickness

- 2.6 mm

- Compliance Standards

- IS 2750, ASTM

- Load Bearing Capacity

- 1.5 to 2 tons per set

- Connection Type

- Pin Type/Lock Type

- Usage

- Internal & External Scaffolding

- Packaging

- Stacked/Bundle Packing

- Vertical Pipe Thickness

- 2.6 mm or as required

- Life Span

- Over 10 years with proper maintenance

- OEM Service

- Available

- Frame Spacing

- Up to 2 meters

Scaffolding H Frame Trade Information

- Minimum Order Quantity

- 50000 Kilograms

- Main Domestic Market

- All India

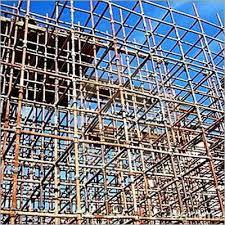

About Scaffolding H Frame

With our rich industry experience, we are engaged in offering Scaffolding H Frame, which finds application in various industries like electronic, automobile and aviation. This Scaffolding H Frame is manufactured with the quality-tested stainless steel under the guidance of skilled technocrats in compliance with the international standards. The offered frame is available in different specifications as per the precise needs of clients within the promised time frame. This is an best way for reaching at heights to accomplish repair, construction, maintenance and housekeeping works.

Technical Specifications

| Height | 7-8 Feet |

| Color | Black |

| Surface Type | Galvanised |

| Width | 5-6 Feet |

| Material | Metal |

Versatile Support for High-Rise Projects

Designed for demanding construction and maintenance tasks, the H Frame scaffolding is built to withstand loads of up to 2 tons per set. It suits both internal and external applications, especially in high-rise building works. Its welded tubular steel construction, corrosion-resistant coatings, and modular design offer users outstanding durability and adaptability, significantly extending its operational life with routine maintenance.

Reliable Performance and Safety Standards

This H Frame meets stringent safety benchmarks, including IS 2750 and ASTM compliance, ensuring reliability on every site. The pin or lock type connections deliver secure assembly, while the structures 2.6 mm thickness provides extra safety. The accessory setmain frame, cross braces, joint pinscompletes a safe and stable platform for all height requirements.

Customizable and Easy to Use

We recognize diverse project needs, offering customization in dimensions and colors as required. The scaffolds modular parts and intuitive assembly make it quick to erect or dismantle, minimizing downtime. Available in various finishes and colors, the system is suitable for both rental and permanent ownership, ensuring ease of integration and maintenance.

FAQs of Scaffolding H Frame:

Q: How is the H Frame scaffolding assembled and what connection types are used?

A: The H Frame scaffolding is designed for easy assembly using either pin type or lock type connections. All components, including the main frame, cross braces, and joint pins, slot together securely, ensuring stability and safety during use.Q: What are the benefits of the H Frame scaffolding for construction projects?

A: This scaffolding system combines high durability, corrosion resistance, and a substantial load-bearing capacity of up to 2 tons per set. Its easy assembly/disassembly, long lifespan (over 10 years with proper care), and customizability make it ideal for fast-paced construction and maintenance work.Q: Where can this scaffolding system be utilized?

A: The H Frame is suitable for a wide range of applications, including internal and external scaffolding for construction, high-rise buildings, and maintenance projects. It is well-suited for both industrial and residential sites.Q: What customization options are available for the scaffolding?

A: We offer customization for dimensions and color according to project requirements. OEM services are also available, allowing clients to specify particular features, branding, and packaging preferences.Q: What is the maximum load this scaffolding can safely support?

A: Each set has a load bearing capacity of 1.5 to 2 tons, and each frame provides a platform loading capacity of up to 250 kg. This ensures robust support for workers and materials during intensive projects.Q: How is the scaffolding packaged and shipped?

A: For efficient transport and onsite handling, the scaffolding is provided in stacked or bundled packages. We accommodate both domestic and international shipping requirements as an experienced exporter, manufacturer, and supplier based in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Scaffolding Category

Scaffolding Material

Price 60 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Material : Aluminum, Steel

Components : Other, Frame, cross brace, lock pins, base plate

Technique : Other, Hot rolled / Welded

Product Type : Scaffolding Frame

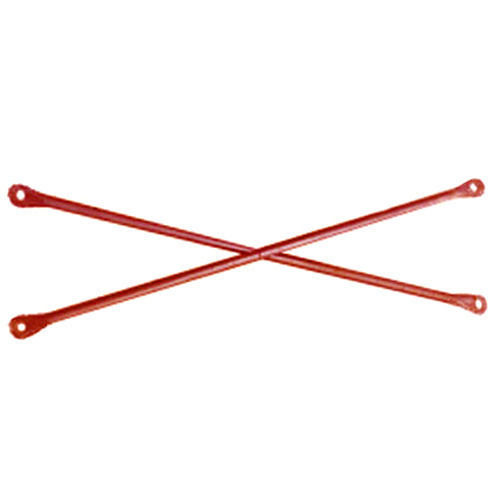

Cross Brace Scaffolding

Minimum Order Quantity : 50000 Kilograms

Material : Other , Mild Steel (MS)

Components : Other, Cross Brace

Technique : Other, Pressed/Stamped

Product Type : Other, Scaffolding Cross Brace

Industrial Scaffolding

Price 62 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Material : Steel

Technique : Forged

Product Type : Scaffolding Props

Construction Scaffolding

Price 50 INR

Minimum Order Quantity : 1 , , Kilograms

Material : Steel

Components : Tubes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese